| OptiStruct案例 |

|

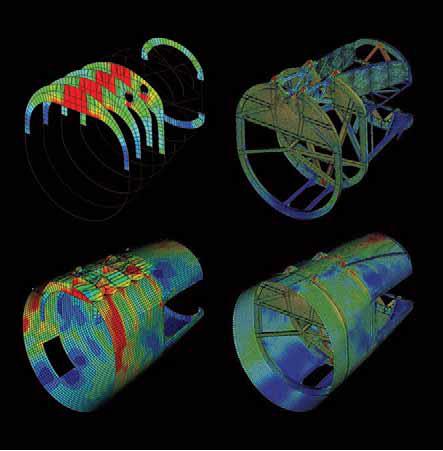

Bloodhound SSC: On Track to Break the World Land Speed Record |

Forklift Manufacturer Cuts Pre-Processing Time in Half and Solves Stubborn Design Problems with Altair’s HyperWorks Suite |

|

Engineering Trade-off between Performance Enhancement and Weight Reduction For Gear Housing Using Mathematical Optimization |

|

HyperWorks Improves Development Processes in Automotive Industry |

|

HyperWorks Improves Development Processes at Automotive Consultancy |

|

Increasing the Customer Value of Structural Designs Using HyperStudy and Topology Optimization While Considering Manufacturing Constraints |

|

Improving Efficiency and Accuracy at Eaton Aerospace with HyperWorks Download Eaton_Aerospace_Success_Story_032210_web.pdf (0.78 MB ) |

|

锁定自行车货架伙伴关系 |

|

充分利用铸造流程 |

|

使钢更轻 |

|

优化:采用不同的设计 |

|

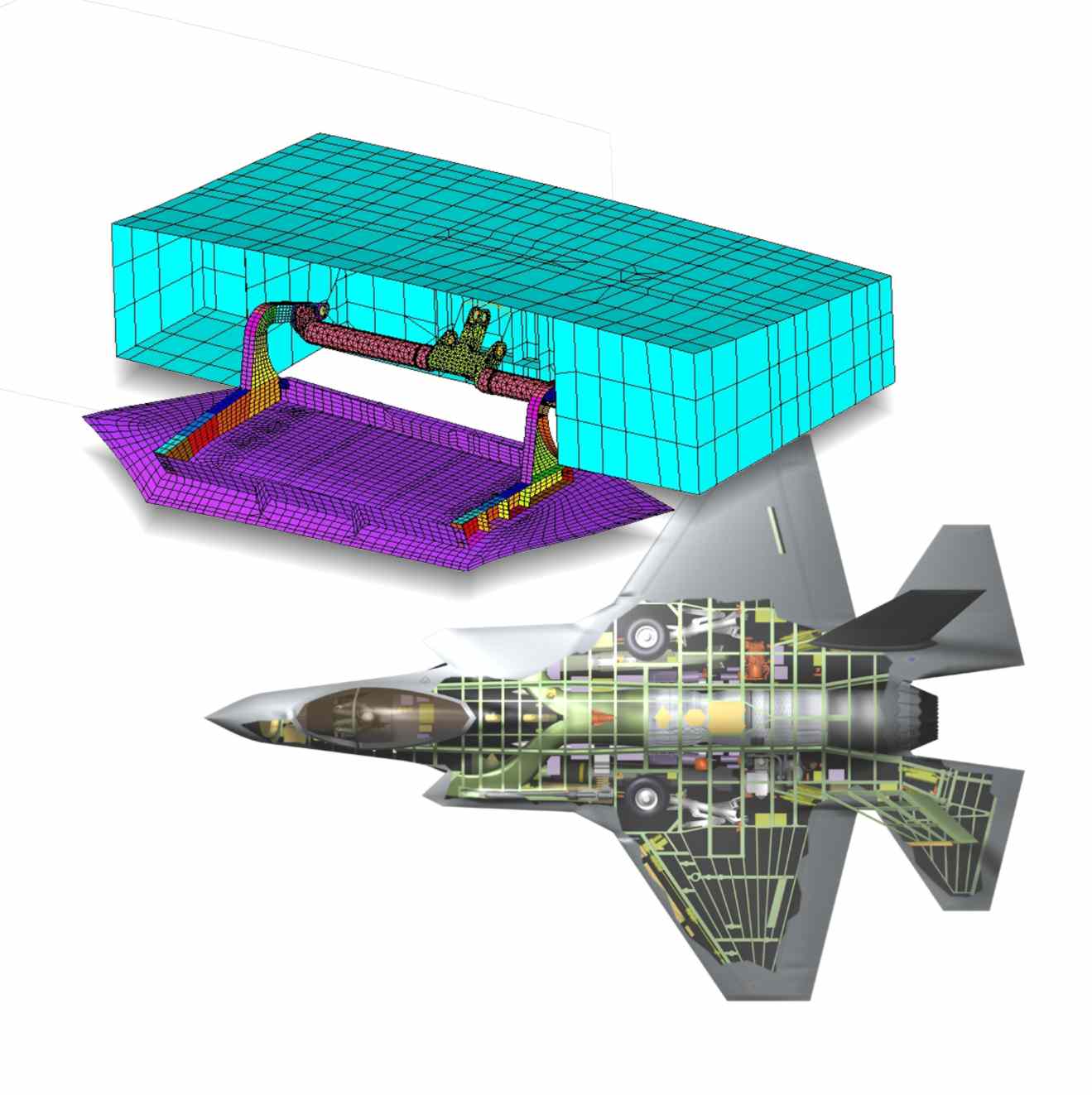

F35联合攻击机结构部件优化 Download LockheedMartin Presentation OTC 20005.pdf (6.35 MB ) |

|

优化帮助军用运输飞机结构优化设计 |

|

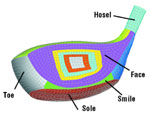

汽车部件概念设计优化 |

|

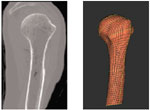

应用拓扑优化设计全地形车骨架 |

|

HyperWorks在长春客车公司:加速高速列车的设计和分析 |

|

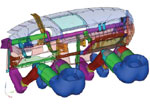

OptiStruct驱动商用飞机减重:舱门支撑臂设计优化 |

|

将仿真应用到运动型概念车设计中 |

|

旋翼飞机设计 Download C2R_Summer2006_TheArtofInnovation_Web.pdf (1.92 MB ) |

|

优化飞机结构 Download C2R_Winter2006_OptimizingAircraftStructures_scrn.pdf (0.52 MB ) |

|

Altair HyperWorks加速轻量Alpine列车开发 |

|

Altair HyperWorks帮助Joe Gibbs赛车 |

|

优化驱动产品性能 |

|

消防车设计 |

|

改善Viessmann供热锅炉声学:OptiStruct优化筋条布局 |

|

PBS Professional在Scripps研究所的应用 |

|

产品开发的成功,取决于对创新的追求 |

|

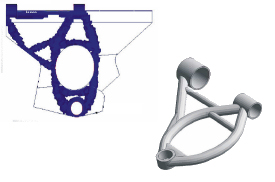

HyperWorks结构优化减少Alfa Romeo悬架设计时间 |

|

OptiStruct技术在早期的概念设计阶段完成铸造和锻造件减重 |

|

OptiStruct在ArvinMeritor公司设计重量轻和更耐用门窗调节升降板时缩短了开发时间 |

|

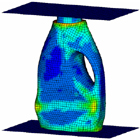

优化包装设计方法 |

|

优化设计驱动新的个人消费护理产品包开发 |

|

优化设计驱动新的个人消费护理产品包开发 |