| HyperMesh案例 |

|

A Solid Idea: Xerox Applies Simulation to Deliver Print Quality |

|

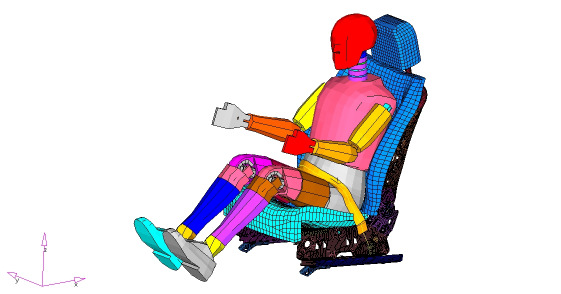

CAD2CRASH24: Driving Full-Vehicle Crash Analysis Down to a Day |

Forklift Manufacturer Cuts Pre-Processing Time in Half and Solves Stubborn Design Problems with Altair’s HyperWorks Suite |

|

MAHLE's Switch to HyperWorks |

|

HyperWorks Improves Development Processes in Automotive Industry |

|

HyperWorks Improves Development Processes at Automotive Consultancy |

|

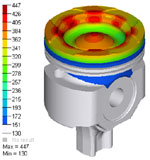

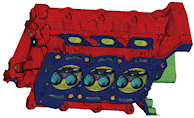

HyperMesh and HyperView customization for thermal analysis of engine systems |

|

Improving Efficiency and Accuracy at Eaton Aerospace with HyperWorks Download Eaton_Aerospace_Success_Story_032210_web.pdf (0.78 MB ) |

|

Cutting physical testing costs by 95% with HyperWorks |

|

Vertical Dynamics of an Offroad Race Car |

|

优化:采用不同的设计 |

|

CAVE虚拟环境提供实时协作平台 |

|

应用拓扑优化设计全地形车骨架 |

|

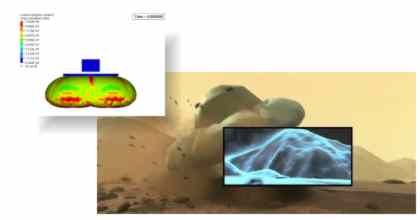

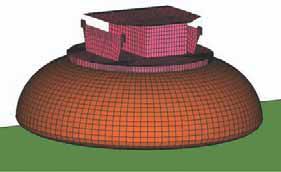

火星漫游者安全气囊设计和可靠性优化 |

|

火星漫游者安全气囊设计和可靠性优化 |

|

HyperWorks在长春客车公司:加速高速列车的设计和分析 |

|

使用Altair HyperWorks加速纳米级产品的开发 |

|

HyperWorks计算流体优化帮助Eberspächer公司提高催化排气进化器寿命 |

|

HyperWorks帮助Dunlop宇航公司节约了其在有限元建模领域50%的时间投入 |

|

OptiStruct驱动商用飞机减重:舱门支撑臂设计优化 |

|

将仿真应用到运动型概念车设计中 |

|

旋翼飞机设计 Download C2R_Summer2006_TheArtofInnovation_Web.pdf (1.92 MB ) |

|

纳米世界的CAE应用 |

|

火星探测计划中的着陆优化方法 |

|

仿真驱动流程化手机研发 |

|

Altair HyperWorks加速轻量Alpine列车开发 |

|

HyperWorks定制的CAE自动化流程缩短摩托罗拉手机研发时间 |

|

开放架构的HyperWorks帮助东芝(Toshiba)设计更小巧的硬盘设备来满足市场需求 |

|

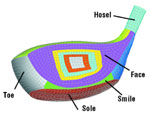

Altair HyperWorks帮助Joe Gibbs赛车 |

|

优化驱动产品性能 |

|

消防车设计 |

|

HyperWorks CAE流程自动化加速Scania产品研发 |

|

PBS Professional在Scripps研究所的应用 |

|

牙刷功能设计 |

|

产品开发的成功,取决于对创新的追求 |

|

领先的焊接分析功能 |

|

风力涡轮机是用于发电技术 |

|

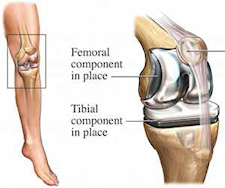

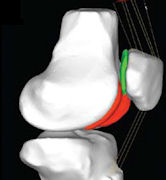

HyperWorks帮助建立基于CT扫描图片的个体化的精确膝关节有限元模型 |

|

HyperWorks计算流体力学优化帮助改进MTU柴油机压气机叶片性能 |

|

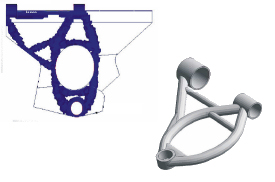

HyperWorks结构优化减少Alfa Romeo悬架设计时间 |

|

使用HyperWorks对发动机性能进行创新设计 |

|

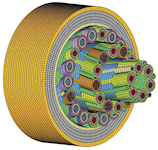

HyperWorks在海底石油和天然气工业中的应用 |

|

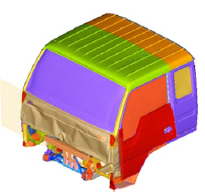

HyperWorks缩减卡车驾驶室设计和原型制造成本 |

|

利用有限元建模方法向膝盖疼痛宣战 |

|

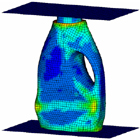

优化包装设计方法 |

|

创新设计分析解决方案处理现代复杂结构 |

|

仿真加速卡车开发流程 |

|

Hawk T Mk2 - Arrestor Barrier (BAN MK2) Engagement Analysis |

|

Fast Tracking Rail Vehicle Design |

|

HyperWorks 帮助长春富奥-江森自控加速汽车零部件的研发 |